4 m x 1.0m Horizontal Process

Filter producing a speciality chemical. The Filter cake solids increase from

55% produced with normal vacuum filtration to over 70% by using a cake

compression drier.

Being pneumatically operated the filter is, by design, intrinsically safe in the local environemt.

8sq. metre Horizontal Vacuum Belt Filter used for recovering nickel in the heap leaching process.

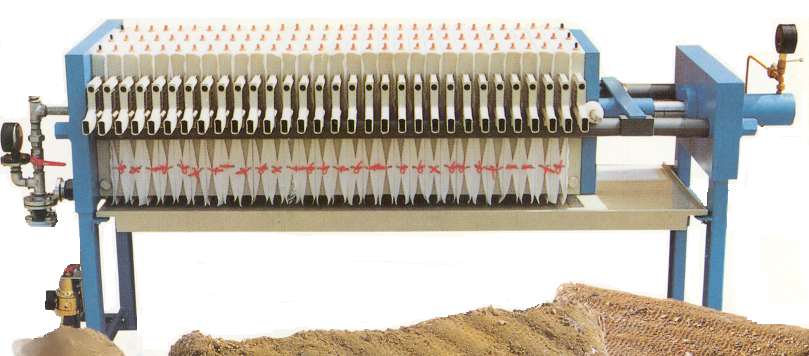

A typical small Filter Press 630mm x 630mm, this one is used in a carpet manufacturing plant to filter the spent latex used for backing the carpets. The design and size is easily adapted for any effluent sludge.

3.5 cubic metre (125cu. ft.) Filter Press. Iron Hydroxide effluent sludge from a stainless steel finishing mill.

Pilot filter - temporary installation to confirm counter current cake washing ratios for the client. Up and working within 4 hours of delivery.

Used on a steelworks metal hydroxide sludge. The plant is located far from the main factory services so in consultation with the client the standard pneumatic drive was changed to hydraulic.

Early counter current cake washing skid with liquid ring vacuum pump water in a closed circuit system cooled via a heat exchanger.

Recovery of Alumimium slag salt for recycling back into the process.

How we work - Two recent successful projects, on vastly differing materials, but following our well proven method serve to show how we work with potential clients.